FIELD SERVICES

Turn-Key Project Management

Acceptance Testing Commissioning & Maintenance

Equipment Upgrades & Breaker Conversions

Infrared Scanning

Safety

Turn-Key Project Management

Exell Power Services offers project single source responsibility and risk management while ensuring project completion to all your requirements. Exell Power Services maintains a staff of highly trained Engineers, Technologists and Technicians offering project management, value added engineering, design, compliance auditing, power system field testing services for acceptance, commissioning and maintenance of electrical power systems and equipment from low voltage through extra high voltage.

Exell Power Services has an extensive amount of experience within our professional workforce. For any of your technical project field services, we can offer:

- Project Planning

- Acceptance Testing and Commissioning

- Maintenance Testing

- System Troubleshooting (24 hour emergency service)

- Power Quality Monitoring

- Electrical Equipment Evaluation

- Accurate and prompt reporting of analysis and findings

Acceptance Testing Commissioning & Maintenance

In Engineering and its various sub-disciplines, acceptance testing is conducted to determine if the requirements of a specification or contract are met. Exell Power Services provides testing to verify equipment function in accordance with design objectives, or specifications. Exell Power performs emergency response or routine maintenance for full service coverage within North America and overseas. Our Maintenance and Testing Services are available for any manufacturers’ electrical distribution equipment.

Preventative Maintenance Services & Agreements:

Exell Power uses the most comprehensive maintenance procedures and offers customer-focused service agreements to help ensure your equipment is maintained properly year after year. Oil testing – oil quality; dissolve gas analysis (GA), PCB content; turns ratio testing; insulation testing; oil filtering or replacing; LTC inspection and testing; power factor testing; repair/replacing of bushings, gaskets, switches, fans, valves, gauges, outdoor structure refurbishment, insulator cleaning, and much more maintenance as required.

Infrared Viewing Windows and Inspections Services:

Safely locate faulty electrical components before they cost money and downtime. Infrared inspections detect abnormal heat produced by electrical systems which may indicate potential electrical problems. Having Infrared windows installed allows you to obtain the condition and status information of electrical components without the need to remove the equipment panels.

Remote Racking Systems:

An innovative state-of-the-art tool for circuit breaker racking and control during maintenance and testing. This system removes the operator from manual contact with the circuit breaker.

Circuit Breakers:

Exell Power Services can supply new, surplus and remanufactured low and medium voltage circuit breakers of all types and all manufactures. Life extension projects are our specialty, and in our modern newly upgraded shop facilities, our technicians can repair, recondition or upgrade your breakers. On-site service is also available. We have numerous spare parts available for immediate shipment. With Exell Power Services skilled technicians, we can provide comprehensive quality service of all types of circuit breakers, switchgear, and other power apparatus.

Partial list of manufacturers’ products we service:

- GE (General Electric)Westinghouse

- Cutler-Hammer

- Siemens-Allis Chalmers

- ABB – BBC – Gould – ITE

- Federal Pacific

- Square D

- Merlin Gerin

- S & C

Preventive Maintenance:

Preventive Maintenance has a direct impact on the life of your equipment. One of the most vital services offered by Exell Power Services is periodic testing and maintenance of your electrical system.

Advantages:

- Keeps your system reliable

- Increases the life term of your electrical system

- Cost-effective solution compared to the cost after a failure

Service Agreement:

A regularly scheduled maintenance programme results in substantial cost savings. Most of them can be attributed to increased uptime of your electrical system, as well as maximum utilization of equipment and facilities.

Features:

- Comprehensive mechanical and electrical testing to ensure proper functional operation

- Recommendations made based on job site findings

- Corrections and repairs can be performed as required

- Testing and maintenance

Equipment Upgrades & Breaker Conversions

Exell Power Services Ltd. offers a complete package to upgrade your protection scheme, from the Engineering to the Commissioning, and testing of any protection system. Upgrading your electrical equipment to meet the current safety codes and standards is a cost-effective way of extending the life span of ageing machinery/equipment, reducing any potential liability, and lowering the existing infrastructure’s environmental impact. Exell Power Services’ Field Service Reps will assess existing equipment on site.

Exell Power Services Ltd. provides a wide range of electrical testing, maintenance and repair services. With our widespread capabilities, and ready to travel anywhere, our competent technicians and technologists will provide comprehensive, quality services of all types of circuit breakers, switchgear, and other power apparatus.

We supply new, surplus and remanufactured low and medium voltage circuit breakers of all types, and all manufacturers. Life extension projects are our specialty; and in our modern shop facility, our technicians can repair, recondition or upgrade your breakers. On-site service is also available. We have on hand numerous spare parts available for immediate shipment.

Retrofits can cost as much as 50% less than the price of new equipment, and installation downtime is significantly reduced while safety is maximized.

Standard equipment modernization services also include:

- Standard Arc Flash mitigation designs and studies

- Engineered designs and full acceptance testing at factory

- Site installation and start-up services

Infrared Scanning

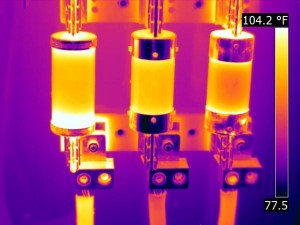

Infrared thermography is a valuable tool in determining the condition of electrical equipment. Basically all objects emit thermal energy, which can be viewed with a scanner, whose purpose is to convert this electromagnetic thermal energy radiated to electronic video signals. Results may be interpreted by obtaining a hard copy (photograph or CD) of the thermal image and determining temperatures at the suspect areas. These temperatures can be compared to equipment thermal ratings and recommendations made.

Loose electrical connections produce heat signatures. Infrared analysis is a simple, cost-effective preventive maintenance measure. Potential electrical problems can be located and then repaired without any interruption of service. Annual inspections are an effective method of fire prevention and more often than not, required by insurers.

This enables corrective action to be taken well in advance of any failure. Regular infrared inspections may also qualify for reduced insurance premiums.

- Advantages:

- Detection of failures

- No downtime required

- Recommendations for corrective action

- Detailed customer report

Abnormal heat produced by electrical systems can indicate a potential problem. This may be a result of:

- system overloads

- loose connections

- broken or oxidized wire strands

- improper grounding

- unbalanced loads

- incorrectly adjusted equipment

- issue with inductive heating

- high resistance terminations caused by thermal cycling

As an Exell Power Services’ customer, you will receive a comprehensive report for every inspection which includes:

- scan date and time

- device temperature

- a reference image

- an infrared image

- recommendations for corrective action

Our report may be customized as required, to include equipment photos, device designations, and more extensive and detailed temperature readings etc., as requested.

Safety

Exell Power Services is committed to safeguarding our people. We believe that safety, quality and productivity are mutually dependent and when diligently managed will provide challenging and satisfying work experiences in a safe and healthy environment. Our directors, managers, supervisors, employees and contractors are responsible to follow and actively engage themselves in following our Health & Safety practices.

Safety is Our Priority. Exell Power Services believes Safety in the workplace is of the utmost importance. Exell Power has established a comprehensive safety program that meets (or exceeds) current standards. Our employees have shared their distinctive knowledge through safety presentations.

The announcement of CSA Z462-08 “Workplace Electrical Safety” brings a set of standard workplace practices, guidelines and tools to meet common electrical hazards faced, including Arc Flash.