Industrial

Pulp and Paper Annual Distribution Maintenance and Testing

Substation Preventive Maintenance and Testing

Industrial Bi-Annual Protective Relay Testing

DSP high resistance grounding system upgrade, various sites in British Columbia

20kV Skid Mounted Transformers and 6.6kV Skid Mounted Distribution Equipment

AESO LSSi Program Integration

Sawmill Arc Flash Mitigation, Central British Columbia

Pulp mill 15kV Distribution Bus Protection upgrade, Central British Columbia

Sawmill Custom lockout cubicles, Florida

Engineering Studies, Various sites in British Columbia/Alberta

Sawmill 69kV substation protection upgrade, Central British Columbia

Engineering site audits, various sites in British Columbia/Alberta

69kV Substation Commissioning

Pulp and Paper Annual Distribution Maintenance and Testing

Overview:

Provide preventive maintenance planning, scheduling and management to meet insurance and regulatory body’s requirements for distribution and generation electrical equipment during the annual 10 to 15 day shutdown. Exell provides a team of technicians that work closely with site personnel to perform maintenance and testing as follows.

- 15KV Switchgear/5KV Switchgear/600V Switchgear

- Circuit breaker contact integrity tests, insulation integrity tests, timing and operational tests

- High voltage cable inspection and insulation integrity tests

- Low voltage circuit breaker secondary and primary injection tests

- Protective relay tests with traceable software

- 138KV/15KV/5KV Transformers both oil and dry type testing and inspections

- Retrofits and upgrades to existing equipment

- Bus protection upgrades from design, fabrication, install and commissioning

- Modifications to existing switchgear to support site projects

Substation Preventive Maintenance and Testing

Overview:

Provide preventive maintenance and testing to meet insurance and regulatory body’s requirements for distribution electrical equipment for numerous wood products companies throughout BC and AB. Exell provides a team of technicians that work closely with site personnel to perform maintenance and testing as follows.

- Incoming 138/69KV Oil/Vacuum/SF6 Breaker contact integrity tests, insulation integrity tests, timing and operational tests

- Transformer insulation integrity tests, winding resistance, excitation and Doble power factor testing

- High voltage cable inspection and insulation integrity tests

- Protective relay tests with traceable software

- Detailed reporting

Industrial Bi-Annual Protective Relay Testing

Overview:

Bi-Annual Protective Relay testing at a large industrial facility for maintenance and insurance verification using traceable, auditable automated software to run test equipment and generate report.

- Inspection and cleaning of protective relays

- Verification of settings as per engineering documents, coordination study and other studies for generator, motor, transformer, directional overcurrent, frequency and high speed bus settings with blocking functions from downstream devices for arc flash mitigation.

- Testing of all functions from simple overcurrent to complex generator, motor, frequency, bus differential, incoming directional, and complex bus overcurrent on in service settings

DSP high resistance grounding system upgrade, various sites in British Columbia

Overview:

Remove failed vintage DSP-Mk 2 with state of the art I-Gard DSP Ohmni.

- Provided updated control drawings

- Supplied and installed pre-wired I-Gard DSP systems for minimal outage.

- Installation and commissioning including primary current injection and feeder tripping

- Programing of feeder priority tripping

20kV Skid Mounted Transformers and 6.6kV Skid Mounted Distribution Equipment

Overview:

Provide commissioning services protection and control from instrument transformer, protective relaying and associated wiring for skid mounted transformers and distribution equipment. Provide setup, commissioning and training for maintenance and operation of skids on site in the Middle East.

- Instrument transformer testing for ratio, polarity, saturation and insulation integrity

- Testing of all protective relays using traceable, auditable automated software to run test equipment and generate report

- Site set up of skid mounted transformers and distribution equipment including setting of protective relays to customers engineering

- Demonstrate operation and maintenance for all equipment supplied

- Initial site operation of equipment in mine

AESO LSSi Program Integration

Overview:

Exell Power Services was invited to engineer, build and install power distribution equipment and an automation system to meet the utilities requirements. Extensive design and custom equipment was implemented. The project was one of five successful sites that were able to meet the requirements set out. Nine projects were awarded.

- Automated tracking, recording and reporting system for integration with the Alberta utility

- Communications, data processing and network were installed

- Load Shed sensing and tripping capabilities engineered and install to meet stringent requirements

- Custom switchgear and retrofit breakers were designed fabricated and install to meet the requirement.

- Engineered tests and approvals were executed to meet the specifications.

Sawmill Arc Flash Mitigation, Central British Columbia

Overview:

Turnkey installation of an arc flash detection system with high speed breaker to reduce the clearing time of an arc flash. Thereby reducing the exposure to workers.

- Supplied control drawing

- Supplied and installed a high speed breaker with a clearing of 16ms

- Supplied and installed fibre and point sensors through the MCC buckets and bus.

- Supplied and installed arc flash relays with onboard event recording

- Commissioning of entire system.

Pulp mill 15kV Distribution Bus Protection upgrade, Central British Columbia

Overview:

Replacement of electro-mechanical relays with MiCOM relays. Exell Power Services was responsible for the installation and pre-wiring of all protection in addition to testing all setting and onsite commissioning.

- Pre-wire and install relays

- Supplied, Installed and tested CT’s

- Supplied custom doors for MiCOM relays

- All Protection settings tested before and after installation.

- Onsite commissioning including all function testing and trip testing.

Sawmill Custom lockout cubicles, Florida

Overview:

Turn-key supply of six lock out cubicles that provided a lock out point near to the equipment being worked on. Included ground fault indication and custom automated lock out test program.

- Cubicles were provided with three separate designs as requested by the client

- Supplied control and mechanical drawings.

- Supplied automated lock out test program that interfaces with site PLC.

- Performed function testing and insulation resistance testing on each cubicle.

- UL certified

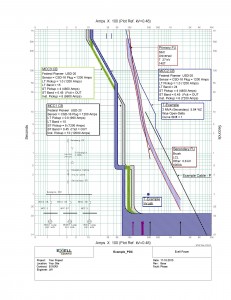

Engineering Studies, Various sites in British Columbia/Alberta

Overview:

Detailed engineering studies which included site visits to visually examine equipment. Reports included recommendations that can be implemented to reduce arc flash incident energy and improve coordination and reliability.

- Utilized Canadian Electrical Code 2012, CSA Z462-12 and IEEE 1584

- All models were created and stored in ETAP 12.5

- Provided arc flash labels and detail reports to include recommendations that can be realistically implemented.

- Coordinated with management to determine timelines and budgets.

- Has since provided ongoing engineering support as the client’s needs change.

Sawmill 69kV substation protection upgrade, Central British Columbia

Overview:

Turnkey upgrade of a 69kV substation protection which added transformer differential protection and voltage protection. This reduced the chance of serious damage occurring to the main transformer due to a major fault which would have seriously affected production.

- Supplied electrical and control drawings

- Removed existing failed overcurrent relays and under frequency relay

- Supplied and installed two new relays for primary and backup protection.

- Provided new protection including overcurrent, transformer differential, under/over voltage and under frequency protection.

- The supplied relays include power monitoring, communications and event recording of all trip events.

- Supplied updated coordination and settings

- Performed ratio and polarity tests on existing CT’s.

- Supplied, Installed and tested PT’s on the secondary of the transformer for metering and protection.

- Commissioning and function testing.

- Witness testing for BC Hydro

- Provided 1 day training after install for site personal

Engineering site audits, various sites in British Columbia/Alberta

Overview:

Provided onsite top to bottom site audits with our team of engineers and field service personnel, supplied reports with recommendations on improving safety and reliability.

- Onsite audit with our team of engineers and field service personal to highlight safety and reliability concerns

- Reviewed existing arc flash and coordination studies, review recommendations.

- Reviewed vintage equipment and determine obsolescence.

- Liaised with management to implement timelines and budgets for the recommended upgrades

- Provided reports with detailed recommendations that are site specific and a realistic.

69kV Substation Commissioning

Overview:

Provide commissioning services for 69kV substation consisting of 69kV SF6 circuit breaker, 69kV disconnect switches, 69kV potential transformers, 20MVA transformer and 25kV switchgear.

- Apparatus testing of 69kV SF6 circuit breaker, insulation integrity including insulation power factor, contact integrity, breaker timing and travel tests

- Apparatus testing of 69kV disconnect switches, insulation integrity, switch alignment and contact integrity

- Apparatus testing of 20MVA transformer, turns ratio, winding resistance, insulation integrity including insulation power factor, auxiliary device testing

- 25kV cable hipot testing

- Apparatus testing of 25kV circuit breakers, insulation integrity, contact integrity and vacuum integrity

- Instrument transformer testing for ratio, polarity, saturation and insulation integrity

- Testing of all protective relays using traceable, auditable automated software to run test equipment and generate report